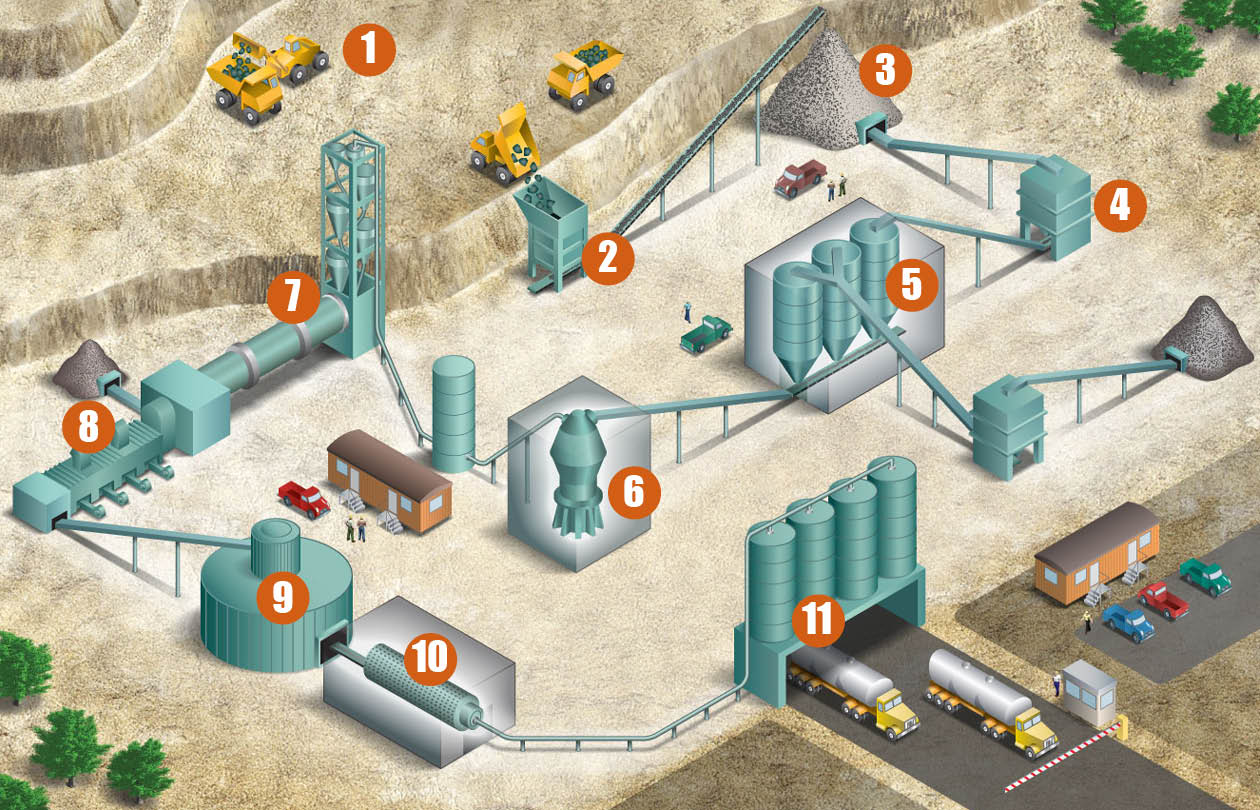

1. QUARRY

Limestone, clay and marl is blasted or scraped up in the quarry and fed into the cement process via dump trucks which dump the material into the primary crusher.

2. PRIMARY CRUSHER

Materials extracted from the quarry are first crushed down to a maximum size of about 6” (150 mm). The crushed material falls onto a belt, or series of belts, which takes it to the limestone stockpile.

ISSUES

- Limestone is still relatively large with sharp corners and causes belt damage under the crusher and at transfers.

- Spillage under the crusher requires cleanup or it can result in damage to conveyor structure and the belt

SOLUTIONS

DRX™ Series Impact Beds under the primary crushers provide load zone support to protect the belt and extend belt life.

Flex-Lok™ and Flex-Seal™ Skirting Systems paired with Urethane Skirting contain material and keep the impact area free of build-up to keep clean up to a minimum.

Sharp pieces of limestone moving through the tail pulley can damage the pulley, lagging, splices and belt. The Flexco V-Plow discharges materials from the return side of the belt, protecting the tail pulley and the belt.

MMP Precleaners and MHS Secondary Cleaners are ideal at the primary crusher where wider belts travel at faster speeds. The robust designs of these cleaners can handle the high tonnage and abrasion caused by larger materials found earlier in the process.

3. LIMESTONE STOCKPILE

Limestone is stored/piled and ready to be belted to the secondary crusher.

ISSUES

- Carryback building up on structures and falling into piles below the belts requires manpower for cleaning. Often belts to the limestone stockpile are long and the quarry is in a remote location relative to the plant, making cleanup and maintenance more time consuming.

- Even after crushing, the limestone is still relatively large with sharp corners, causing belt damage.

- Mistracking belts are causing damage to belt edges, and these longer belts are costly to repair or replace.

SOLUTIONS

MMP Precleaners and MHS Secondary Cleaners hold up in abusive applications like this one with long-wearing urethane and carbide blades that reduce maintenance and cleanup time.

Flex-Lok™ and Flex-Seal™ Skirting Systems at transfers seal the load zones to reduce cleanup in these areas, which can oftentimes be remote and difficult to service.

Slider Beds or Impact Beds at transfers can be used to protect belts from conveying quarried material to the stockpile. The slider bed with impact rollers is a great choice for containment in the lower impact load zones. DRX™ Impact Beds provide exceptional belt protection in this abusive, high-impact environment.

PTEZ™, PT Smart™, or PT Max™ Belt Trainers address center loading issues, discouraging product loss and belt damage. PTEZ™ and PT Smart™ are recommended for medium-duty belts going to the stockpile, while the PT Max™ is ideal for steel cable or high-tension belts.

4. SECONDARY CRUSHER

Used to take larger quarried material that has been crushed once to less than 6" (150 mm), and crush it down to under 1" (-25 mm) to prepare it for storage and proportioning.

ISSUES

- Rocks are dropping down under the stockpile and damaging the belt.

- There may be limited space to access the impact zone under the secondary crusher.

- If the limestone stockpile is not covered, wet/sticky material builds up on idlers and structure causing mistracking, idlers to seize, and leads to belt damage.

- Sticky carryback material piles up on the ground and builds up on conveyors and other equipment.

SOLUTIONS

Flex-Lok™ and Flex-Seal™ Skirting Systems seal the area to keep dust and spillage to a minimum in the confined or hard to clean space.

Slider Beds or Impact Beds can be used to protect belts. For lower impact areas, the EZSB-I Slider Bed with impact rollers is a great choice for containment in the load zone. For higher impact areas, DRX™ Impact Beds provide superior belt protection in this abusive high-tonnage environment. The slide-out service of the DRX impact beds also make maintenance fast and easy in confined spaces.

H-Type™ Precleaners provide efficient cleaning on vulcanized belts, keeping materials from travelling back to the stockpile and possibly underground. For mechanically fastened belts, the robust design and long-lasting urethane formulation of the blades on the MSP Standard Mine-Duty Precleaner and MMP Medium Mine-Duty Precleaner are perfect for belts that may see more than 2 million tons of material a year.

Due to the amount of material carried on this belt, multiple secondary cleaners may be used. A Y-Type™ Secondary Cleaner can handle both wet and dry materials in this area, while a U-Type® Secondary Cleaner will be ideal if the limestone stockpile is outdoors and material is wet or sticky.

SECONDARY CRUSHER SUPPORTING PROCESS

Additional raw materials that are not from the quarry may be brought into the process here and may require crushing.

ISSUES

- Wet, sticky clay sticking to the belt, building up on idlers and structures.

- Containing the wet, sticky clay on the belt is a challenge and requires cleanup time when spilled.

SOLUTIONS

MSP Precleaners and U-Type® Secondary Cleaner can help combat wet and sticky materials.

Flex-Lok™ and Flex-Seal Skirting Systems seal the area, and can often run the full length of the conveyor because of the relatively flat nature of the belt.

Adjustable Idler Set with Impact Rolls support the belt while reducing belt drag in this low-impact area.

Flexco® 190 Fasteners provide a robust splice and is durable enough to handle the large rocks that still come through the area.

5. RAW MATERIALS STORAGE AND PROPORTIONING

Crushed limestone and other raw materials like sand, clay, fly ash, and shale are conveyed to raw materials storage where they are mixed together in the needed proportions before going in the rawmill.

ISSUES

- Abrasive materials are causing wear to belt splices, generating splice and belt damage.

- Corrosion is occurring on the equipment that handles fly ash.

- Multiple transfers means the need for more sealing to combat dust and spillage.

SOLUTIONS

Flexco Impact Beds or Impact Slider Beds protect and seal the area, which handles the smaller, low-impact materials.

The spring tensioners on the Y-Type™ Secondary Cleaner with Carbide Blades keep constant pressure on the belt for efficient cleaning at an affordable price.

When fly ash is being handled, stainless steel products like the Stainless Steel EZP1 Precleaner and Flexco® Stainless Steel 140 Fasteners are recommended. They will last longer and, in the case of the fasteners, provide longer life to the splice and belt.

The conveyors in this area are often enclosed, which helps contain material and reduce fugitive dust, but servicing cleaners can be a challenge. Inspection doors are a great option for speeding up inspections and maintenance.

Flex Seal™ and Flex-Lok™ Skirting Systems can keep material from spilling out and falling through storage silos/bins

Splices have a tendency to wear out quickly in this area, so the FSK™ Belt Skiver can be used to remove the belt top cover prior to installation. The lower profile splice helps maximize the splice life.

6. RAWMILL

In Dry Processing, materials are fed into the mill dry and crushed into a fine powder. In Wet Processing, materials are fed into the mill and water is added and the mixture is crushed into a slurry.

ISSUES

- Material escaping the load zones creating hazardous piles and requiring cleanup.

- Mistracking is causing belt damage and material loss.

SOLUTIONS

EZP1, MSP, and MMP Precleaners help combat carryback that are causing material buildup and dust.

For a crucial belt like this, the long lasting carbide and spring tensioner of the Y-Type™ Carbide Secondary Cleaner is attractive because of its effectiveness and ease of maintenance. Blade change-outs can be done in a matter of minutes and materials are effectively cleaned off the belt.

Minimize belt damage and material loss by making sure the belt is centered while travelling through the tail pulley by using a PTEZ™ Belt Trainer.

Flex-Seal™ Skirting System seals the load zone to contain the very fine materials that drop onto the belt during this process.

Lighter DRX™ Impact Beds or Flexco Impact Beds are ideal for this low-impact area. If there are multiple load points on this belt, impact idler sets can be used between beds.

Material can be abrasive so a robust splice created by using Flexco® 190 Fasteners, is required on the belt feeding the rawmill.

7. PYROPROCESSING

The pyroprocessing step includes the preheater tower and kiln which heat up the crushed raw materials (called “raw meal”) and sinter them into clinker. Slurry or raw meal powder is conveyed to the pyroprocessing phase via bucket elevators or compressed air. Fuels for the kiln are conveyed in via drag chains or conveyor belts.

ISSUES

- Coal dust carryback or spillage piles are considered an explosion hazard, which is dangerous and cause the cement plant to be fined.

- The kiln needs fuel to keep making clinker so downtime on these belts is costly.

SOLUTIONS

For Coal Belts:

Lighter-duty DRX™ or EZSB Impact Beds are great choices for sealing under the coal stockpile, making sure belt is properly supported and sealed to avoid coal and dust escaping the load zone.

Containing coal dust is vital in this process, so the Flex-Lok™ or Flex-Seal™ Skirting System is important.

EZP1 and MSP Precleaners and Y-Type™ Carbide Secondary Cleaners address carryback issues with coal dust, minimizing the chance of explosions and fines from regulatory agencies.

Flexco® 190 Mechanical Fasteners can be installed quickly to maximize uptime. Fasteners like the 190 are also sift-free, so coal fines aren’t being spread around the plant on belts that may be high off the ground.

The PTEZ™ Belt Trainer is the perfect choice to help long belts that may get off track while moving coal to the coal mill building.

Other Kiln Fuels:

Depending on how close the head pulley is to the kiln, the MSP Precleaner with High Temp Blade may be required for finer materials like sawdust and chipped plastics.

Impact beds may be needed to protect the belt for larger fuels like tires, although these belts may be completely flat and the impact low.

8. CLINKER COOLER

Clinker is moved on perforated metal grates as air is forced into the cooler, bringing the clinker temperature down as quickly as possible. Cooling the clinker in a timely manner allows it to be conveyed without damaging equipment and faster cooling enhances silicate reactivity in the cement. Clinker will still be hot after the clinker cooler, but in many instances it is cool enough to be conveyed on a belt.

9. CLINKER STORAGE

Clinker is conveyed to storage silos or to a storage warehouse where it is stays until going to the finish mill.

ISSUES

- When water is used to further cool clinker, it is splashing and the hardening dust is adhering to the belt.

- The abrasive nature of clinker is causing the idlers and cleaners to wear out quickly.

- Hardened clinker dust is building up on idlers causing belt mistracking.

- Hot clinker is causing cracks in the belt, making cleaning difficult and leaving crevices in which clinker fines is settling and traveling to other parts of the operation to fall.

SOLUTIONS

The High Temp HV or the yellow urethane blade on an EZP1 and MSP Precleaners are ideal for these belts, depending on whether the belt is vulcanized or mechanically fastened. The carbide blade and high temp yellow urethane blade are both great for high temp and abrasive applications.

High-Temp Y-Type™ Carbide Secondary Cleaners are easy to install and maintain, maximizing uptime on belts that need carryback removed before materials harden.

Urethane Skirting lasts 3-4 times longer than rubber and is perfect for the extremely-abrasive clinker being conveyed during this process.

The impact is not extremely high on belts moving clinker, so sealing the load zone with low-resistance Flexco Slider Beds with Impact Idlers is a good option.

PTEZ™ Belt Trainers help keep the belt away from the structure and do not have sensor rolls, so they can’t damage belt edges and vulcanized splices. The minimal exposed componentry makes it a good candidate where clinker dust often settles and hardens.

Clinker transfers are often completely enclosed chutes, so inspections and maintenance can be difficult unless Inspection Doors are used.

10. FINISH MILL

Clinker is conveyed from storage to the finish mill, where the nodules are ground into a fine powder.

ISSUES

- Dust is generated when removing the clinker from storage.

- The abrasive nature of clinker is wearing out skirting and idlers quickly, especially when it gets in the bearings. Enclosed belts need to be opened to inspections, which is difficult and time consuming.

- Round clicker nodules are rolling around the belt and bouncing off, especially on inclines.

- A horizontal finish mill requires frequent inspections as the mills take a lot of abuse. The steel balls that crush the clinker into fine powder are wearing out and breaking internal components in the mill.

SOLUTIONS

EZP1 Precleaners and Y-Type™ Carbide Secondary Cleaners utilize Flexco’s unmatched urethane formulation to tackle abrasive clinker dust for longer wear. The Y-Type’s simple blade change design means quick changes can be done when the mill is down for inspection.

The sift-free design and quick installation of Flexco® 190 Mechanical Fasteners limits downtime during this process.

To minimize gypsum and clinker dust escaping when brought from storage, the load zone needs to be properly supported utilizing Flexco Impact Beds, Slider Beds, and Impact Idlers. The impact likely will not be high in this area, but it does require support.

Flex-Seal™ Skirting Systems and Skirtboard can ensure that all the clinker nodules make it into the mill instead of falling off the belt.

11. STORAGE AND SHIPPING

Finished cement product leaves the finish mill and is conveyed pneumatically in pipes to storage silos, where it can be loaded onto trucks, rail cars, ships, or bagged at the “pack house.”

ISSUES

The gap between belts is damaging bags, creating a big mess.

SOLUTIONS

Alligator® Staple Fasteners features a beveled front edge that reduces the chance of a bag ripping on a splice.

Segmented Transfer Plates can reduce the chance of tearing/splitting a bag by bridging the gap between two belts.