Logistics Spotlight: Increasing Output by Replacing Pop-Out Rollers at Your Belt Conveyor Transfers

|

| Improperly guarded conveyor transfers can result in package jams and damaged products, reducing output and increasing headaches. |

I’ve been traveling the world for 30 years now, walking the lines of conveyors in a variety of industries – from food to pharmaceuticals, logistics to agriculture – and I when I return, my colleagues often ask me questions like, “What’s the conveyor issue you see the most out in the field that could be solved pretty easily?”

I have to be honest when I say it really depends on the industry and the goals of the operation. But I think we can all agree that anything that affects throughput, productivity, and safety needs to be dealt with immediately.

In the logistics industry specifically, besides safety (which is always No. 1), output is the single most important metric. Whether you are warehousing, distributing, fulfilling, or shipping orders, keeping items on the conveyor and moving them to their next destination is the top priority.

So, if you ask me where I think that isn’t happening as effectively as I think it should in most logistics operations, it’s at the conveyor transfers. Time after time, I see packages ripping open, getting jammed, and even falling under conveyors at transfers and transition points. In addition to reducing output, this issue causes downtime, maintenance headaches, and safety concerns.

Pop-out rollers in conveyor transfers

|

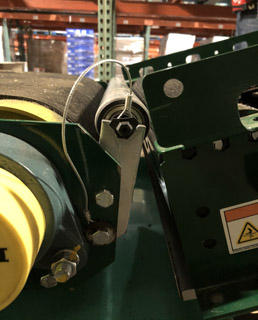

| A tether is often attached to the pop-out roller to keep it from falling under the conveyor, but can be hazardous to those standing near the roller when it dislodges and can also block package flow. |

For this reason the pop-out roller was invented. The aptly-named pop-out rollers rest in notches found at the end of each side of a conveyor structure. They are designed to allow packages to pass over with little resistance and to “pop out” if small parcels become lodged in the transfer. They are also designed to pop out in the event a worker gets their finger or hand caught in the transfer. The “released” rollers then either drop through or continue to move down the conveyor with the packages, freeing the transfer of the jam and keeping packages moving.

But in some cases, pop-out rollers cause more issues than they solve. The quickness of their release is good in some cases, but not when a heavy package simply bounces across the top and the roller pops out of the gap. The unprotected gap that is left in the area can go unnoticed and smaller packages can then fall through or get lodged in the area, while also creating a safety hazard for workers.

In rare cases, pop-out rollers can be a safety hazard in their own right if they pop out of an elevated gap and land on workers or machinery below. For this reason, a cable tether is often employed. This not only stops rollers from falling below, but also stops them from traveling down the conveyor when the roller pops out. But even a tethered roller can become a jam risk for packages as it rests on top of the conveyor belt, blocking the flow.

If not pop-out rollers, what?

The transfer plate solution

|

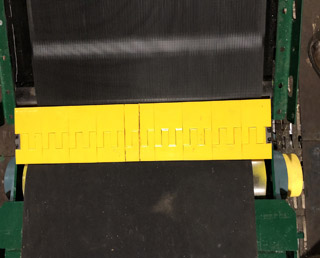

| The Flexco team saw a need for transfer point protection and developed Flexco Segmented Transfer Plates. |

After seeing this issue so many times and knowing there had to be a better way to protect the transfer, we started making a list of everything a potential solution would need to do in order to be effective. To do that, we needed to make sure it was:

- An easy-to-install solution – because downtime is money and even proactive maintenance means the conveyors aren’t running and packages aren’t moving.

- Able to be mounted to the current conveyor structure – and with this in mind, we knew we would probably need a few different installation options.

- Flexible – not all gaps are the same size, so designing it with different size options was crucial to ensure the correct fitment to the belt.

- Versatile – with the ability to dislodge if something got stuck, especially with all the Jiffy® bags, polybags, and envelopes out there these days.

We recognized a need. We listened to customer frustrations. We tested. We trialed. We adjusted. The end result? Flexco Segmented Transfer Plates. These Segmented Transfer Plates check all the boxes and more. First, they are quick and easy to install – with special brackets making 20 minute install times the norm. Second, the plates can be mounted on the existing conveyor structure, with three different install kits for a variety of options.

Read what happened when a major clothing retailer swapped out their pop-out rollers for Flexco Segmented Transfer Plates in their distribution facility here.

|

| A tote slides effortlessly across the transfer after installation of a Flexco Segmented Transfer Plate. |

Next, the design features segments that snap into each side of a mounting bar, with the ability to protect gaps from 1.5” to 10” wide, making it very versatile. And a segment can dislodge in the unlikely event something becomes lodged under it, leaving the rest of the plates to guard the gap until the next scheduled maintenance event. The plate can then be repaired in seconds by simply snapping a new segment in place, resulting in no damage to the belt, conveyor structure, or packages, while significantly reducing conveyor downtime. We also made the plates yellow so a segment’s absence in the gap is easy to spot, while the bright yellow color serves as a cautionary warning to employees to mind the transfer.

Are you ready to protect your transfers … and your bottom line?

Don’t let the simplicity of the design and operation fool you into thinking the addition of Segmented Transfer Plates can’t be a breakthrough in productivity and safety, as well as a boost to your operation’s wallet. A large fulfillment center in Europe saw $1.8 million in downtime savings a day after installing them in four high-risk transfers in their facility.

Authored by: Todd Stewart, Industry Manager

Stewart has been with Flexco for over 32 years, working in various roles from customer service, to manufacturing, to training and new product development. As Industry Manager, Stewart thoroughly researches target industries, creating programs to support each industry and identifying customer issues, as well as potential product solutions. Stewart currently leads the development of the Logistics Industry Program and is responsible for ensuring that Flexco is positioned to serve the needs of our global customers. Stewart earned a bachelor’s degree in Marketing with a B2B specialty from Davenport University.

Subscribe to the Flexco Blog

Related Blogs

Published Date

May 19, 2021Product Group

- Belt Accessories

Industries

- Parcel Handling

- Warehousing and Distribution

Issues

- Belt Damage

- Downtime

- Maintenance

- Product Loss