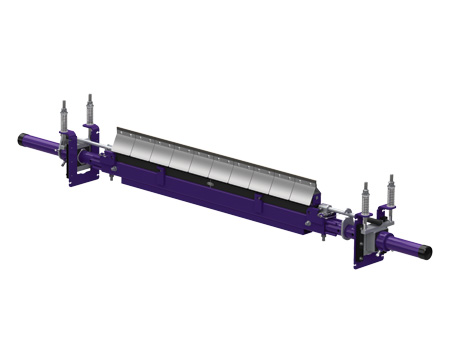

MHS with Enhanced Service Advantage Cartridge (ESAC)

The MHS with Enhanced Service Advantage Cartridge (ESAC) offers superior cleaning and serviceability. The cartridge can be easily removed and replaced, even in the dirtiest conditions. The innovative design limits material build up and prevents corrosion.

Specifications

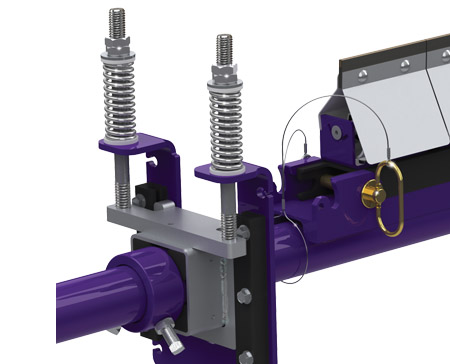

- Dual spring tensioner allows clearance to remove cartridge

- Maximum Belt Speed:

- C-Tip: 1000 fpm (5.0 m/sec)

- V-Tip: 1200 fpm (6.0 m/sec)

- Temperature Rating: -30°F to 180°F (-35°C to 82°C)

- Usable Blade Wear Length: 3/8" (9 mm)

- Blade Materials:

- C-Tip: Impact Resistant Tungsten Carbide (works with mechanical fasteners)

- V-Tip: Long Life Tungsten Carbide (for vulcanized belts only)

- Pole Diameter: 2-7/8" (73 mm)

- Available for Belt Widths: 24" to 120" (600 to 3000 mm)

Installation

- Pole Length:

- Belt width plus 54" (1350 mm) (single cartridge cleaners)

- Belt width plus 60” (1500 mm) (dual cartridge cleaners)

- Horizontal clearance required:

- 4-1/2" (114 mm) (single and dual cartridge cleaners)

- Vertical clearance required:

- 11" (279 mm) (single cartridge cleaners)

- 10" (318 mm) (dual cartridge cleaners)

- Tensioner mounting brackets included for fast and easy installation

- Cartridge Removal Kit included for easy removal of the cartridge

- Products

- Specifications

- Instructions

- Sales Support

SST Tensioner Spring Length Chart

| BLADE WIDTH |

WHITE SPRING |

SILVER SPRING |

BLACK SPRING |

||||

|---|---|---|---|---|---|---|---|

in. |

mm |

in. |

mm |

in. |

mm |

in. |

mm |

| 24 | 600 | 3 1/8 | 79 | 3 7/8 | 98 | N/A | N/A |

| 30 | 750 | 2 7/8 | 73 | 3 3/4 | 95 | N/A | N/A |

| 36 | 900 | N/A | N/A | 3 3/4 | 95 | 3 7/8 | 98 |

| 42 | 1050 | N/A | N/A | 3 5/8 | 92 | 3 3/4 | 95 |

| 48 | 1200 | N/A | N/A | 3 1/2 | 89 | 3 5/8 | 92 |

| 54 | 1350 | N/A | N/A | 3 3/8 | 86 | 3 5/8 | 92 |

| 60 | 1500 | N/A | N/A | 3 1/4 | 83 | 3 1/2 | 89 |

| 72 | 1800 | N/A | N/A | N/A | N/A | 3 3/8 | 86 |

CST Tensioner Spring Length Chart

| BLADE WIDTH |

WHITE SPRING |

SILVER SPRING |

BLACK SPRING |

GOLD SPRING |

|||||

|---|---|---|---|---|---|---|---|---|---|

in. |

mm |

in. |

mm |

in. |

mm |

in. |

mm |

in. |

mm |

| 24 | 600 | 3 1/8 | 79 | 3 7/8 | 98 | N/A | N/A | N/A | N/A |

| 30 | 750 | 2 7/8 | 73 | 3 3/4 | 95 | N/A | N/A | N/A | N/A |

| 36 | 900 | N/A | N/A | 3 3/4 | 95 | 3 7/8 | 98 | N/A | N/A |

| 42 | 1050 | N/A | N/A | 3 5/8 | 92 | 3 3/4 | 95 | N/A | N/A |

| 48 | 1200 | N/A | N/A | 3 1/2 | 89 | 3 5/8 | 92 | N/A | N/A |

| 54 | 1350 | N/A | N/A | 3 3/8 | 86 | 3 5/8 | 92 | N/A | N/A |

| 60 | 1500 | N/A | N/A | 3 1/4 | 83 | 3 1/2 | 89 | 4 | 101 |

| 72 | 1800 | N/A | N/A | N/A | N/A | 3 3/8 | 86 | 4 | 101 |

| 84 | 2100 | N/A | N/A | N/A | N/A | 3 1/8 | 80 | 3 7/8 | 99 |

| 96 | 2400 | N/A | N/A | N/A | N/A | N/A | N/A | 3 7/8 | 99 |

| 120 | 3000 | N/A | N/A | N/A | N/A | N/A | N/A | 3 5/8 | 93 |

Aluminum Content

| ALUMINUM ALLOY TYPE |

PERCENT MAGNESIUM (Mg) |

PERCENT TITANIUM (Ti) |

|---|---|---|

| 6061 | 1.0% | 0.0% |