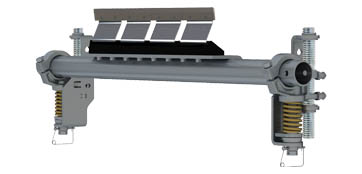

FMS Secondary Cleaner

The FMS Secondary Belt Cleaner features carbide blades, self-adjusting spring tensioners and unique cushions that independently tension each blade to the belt. This simple, but durable, design provides quality cleaning performance at an affordable price. Its compact tensioner is a great choice for limited-space applications.

- Segmented blades with unique sealed cushion design allows each blade to self-adjust and ensure proper wear throughout life of the blade

- Tungsten carbide blades deliver high cleaning efficiency and long wear life

- Tips available for mechanically fastened or vulcanized belts

- CEMA Class 4

- Belt speeds up to:

- C-Tip: 1000 fpm (5.0 m/sec)

- V-Tip: 1200 fpm (6.0 m/sec)

- Belt widths 24" to 72" (600 to 1800 mm)

Browse FMS Secondary Cleaners

Resources

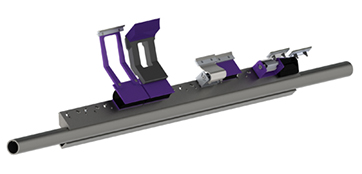

MINELINE®

When standard products just won't do.

Flexco Mineline® products are designed and engineered to work in some of the toughest applications in the world that test the strength and durability of your conveyor system. Products carrying the Mineline® name are proven to work — even where other products have failed.